AI Startup Deep.Meta Pushes UK Steel Toward Lower Emissions

• Deep.Meta’s AI driven simulations achieved close to a 10 percent emissions reduction at Spartan UK, the country’s only steel plate producer.

• The company is developing its Deep.Optimiser PhyX system through the UK government’s Manchester Prize ahead of a one million pound final in March 2026.

• AI assisted optimisation could cut energy use, strengthen competitiveness, and support net zero goals across global steel markets.

A Newcastle steel plant has become the proving ground for an emerging technology that could reshape one of the most carbon intensive industries. Deep.Meta, a young artificial intelligence firm, has demonstrated that its physics based digital twin can reduce emissions from steel production by almost 10 percent at Spartan UK’s facility in Newcastle upon Tyne. The company will now move into a live pilot phase with the site.

Spartan UK has particular strategic weight in British manufacturing. It is currently the nation’s only producer of steel plate. In 2024, the wider sector added 1.7 billion pounds in gross value to the economy. Steel remains a critical backbone of industrial output, yet its environmental cost is high. Globally the sector accounts for roughly 9 percent of carbon dioxide emissions. British climate targets depend on the availability of cleaner industrial production, and investors have increasingly pushed mills worldwide to prove that efficiency, decarbonisation and profitability are not mutually exclusive.

How AI is tightening furnace efficiency

Deep.Meta’s technology, branded Deep.Optimiser PhyX, uses real time sensor data and material science models to create a digital twin of furnace operations. The platform predicts slab temperature, optimises scheduling and suggests operational adjustments that lower energy consumption. Hundreds of production cycles can be simulated within hours instead of months.

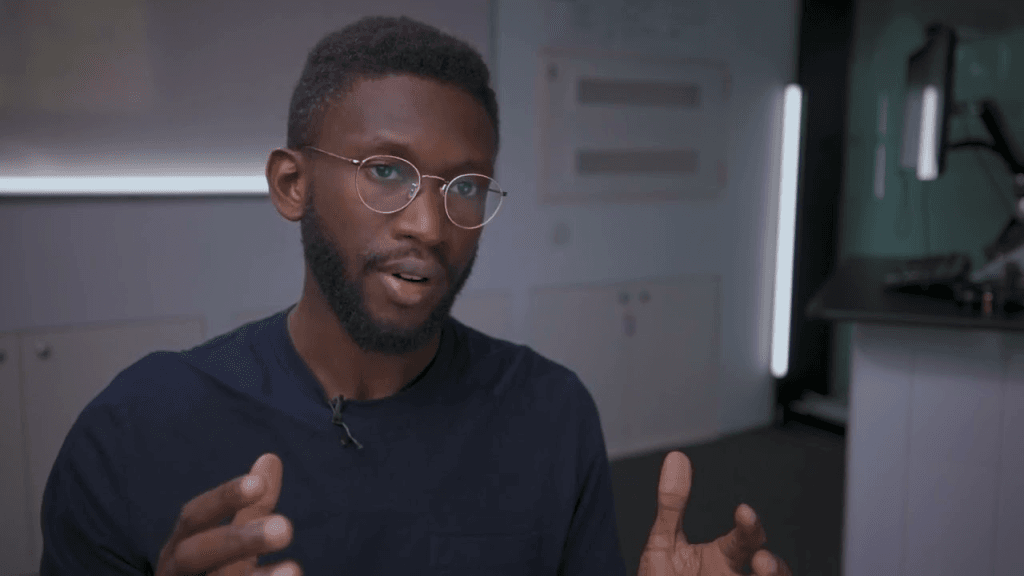

Founder and chief executive Dr Osas Omoigiade says steel decarbonisation cannot advance without more precise process control. “Steel is one of the most important materials on which our society is built. Yet, its production generates 9 percent of all global CO2 emissions. We cannot reach net zero without solving steel’s climate impact. We are developing Deep.Optimiser PhyX to tackle inefficiencies that result in avoidable emissions, a crucial step in helping to decarbonise the industry. Through the Manchester Prize we have been able to integrate physics into our AI platform, which enhances its prediction capabilities further.”

He adds that the company’s long term ambition is to prevent ten megatonnes of CO2 entering the atmosphere by 2030. Work at Spartan UK is intended to provide replicable evidence for wider roll out. “If we are selected as the winner of the Manchester Prize, we want to scale our development work with furnace machine providers for integration across UK producers and continue expanding into other regions, including North America.”

Explainable AI is gaining favour among industrial buyers

Industrial players have often resisted digital optimisation tools due to opaque analytical methods. Deep.Meta argues that coupling machine learning with physical law based modelling has eased trust concerns.

Senior machine learning scientist Dr Kwangkyu Alex Yoo says industry needs models that behave predictably. “Today’s machine learning models often operate as black boxes, lacking fundamental principles that clearly link inputs to outputs. This creates significant resistance when industries attempt to deploy AI technologies in real production environments. Our physics based machine learning approach addresses these challenges by incorporating the underlying physical laws into both the training process and data generation. This leads to models that are more explainable and trustworthy, while enabling more reliable and robust decision making.”

Since 2020 the company has raised 2.1 million pounds. Backing from the Manchester Prize is supporting development of more detailed physics integration to sharpen precision on temperature and timing variables. That could deepen efficiency gains, broaden commercial traction and increase appeal for producers adjusting to carbon pricing pressure.

RELATED ARTICLE: Google Expands AI Mobility Tools Across Brazil, Cutting Fuel Use and Emissions

Energy accounts for forty percent of steelmaking costs

Rising energy prices are one reason UK mills are exploring operational intelligence tools. Spartan UK chief executive Michael Brierley says cost exposure is significant. “Deep.Meta is a trusted partner, and we are piloting the Deep.Optimiser solution, because of the rising costs of energy and carbon. Increasing the efficiency of production is of high importance as energy costs form a significant part of our cost structure. Around 40 percent of steel production costs are from energy and much of this is fossil fuel based, so driving a reduction in energy directly cuts CO2 emissions.”

Better furnace control does more than cut emissions. Higher yield, product consistency and stable production windows are key for commercial competitiveness. That matters in a market where imported steel often competes on price rather than carbon intensity. Digital optimisation could also support workforce retention by making domestic steelmaking more resilient under tightening climate policy.

Chris Oswin, chief executive of the Materials Processing Institute, says innovation determines the future of UK steel. “Innovation will be absolutely central to the future of the UK steel industry and we believe AI will play an important role in improving processes and embracing digital and low carbon solutions. This will enable us to ensure our industry is not only sustained but becomes a global leader. Innovation is the driving force that will keep the UK steel sector competitive, resilient and ready for the decades ahead.”

Jon Bolton, co chair of the UK Steel Council, says industrial policy and technology adoption must progress together. “Collaboration between industry and government is vital if we are to secure a sustainable future for UK steel. The sector is central to our economy and our transition to net zero, and technologies like Deep.Meta’s are the kind of solutions we need to drive that change. By supporting these advances through initiatives like the Manchester Prize, we are helping to create a modern, competitive steel industry that not only safeguards jobs and skills, but positions the UK as a global leader in clean, high value manufacturing.”

The Manchester Prize will award one million pounds to the most impactful clean energy AI solution in March 2026. Deep.Meta is one of ten finalists. For global heavy industry, the pilot at Spartan UK will be watched closely. If replicated across multiple mills, physics informed optimisation could become a realistic bridge to lower carbon steelmaking, opening a path for countries and investors betting on a cleaner industrial base.

Follow ESG News on LinkedIn