Panasonic Expands European Heat Pump Production with $348m Investment

- Panasonic expands Pilsen giga factory to produce up to 1.4 million heat pump units annually by 2030.

- Investment establishes a European hub for production and R&D, aligning with EU decarbonization goals.

- Facility operates as a Net Zero factory powered by renewables, robotics, and automation.

Panasonic has officially opened its expanded and modernized heat pump factory in Pilsen, Czech Republic, following a €320 million ($348 million) investment that will transform the site into one of Europe’s largest heat pump production hubs. The upgraded facility will have capacity to manufacture up to 1.4 million units annually by 2030, serving fast-growing demand across the continent.

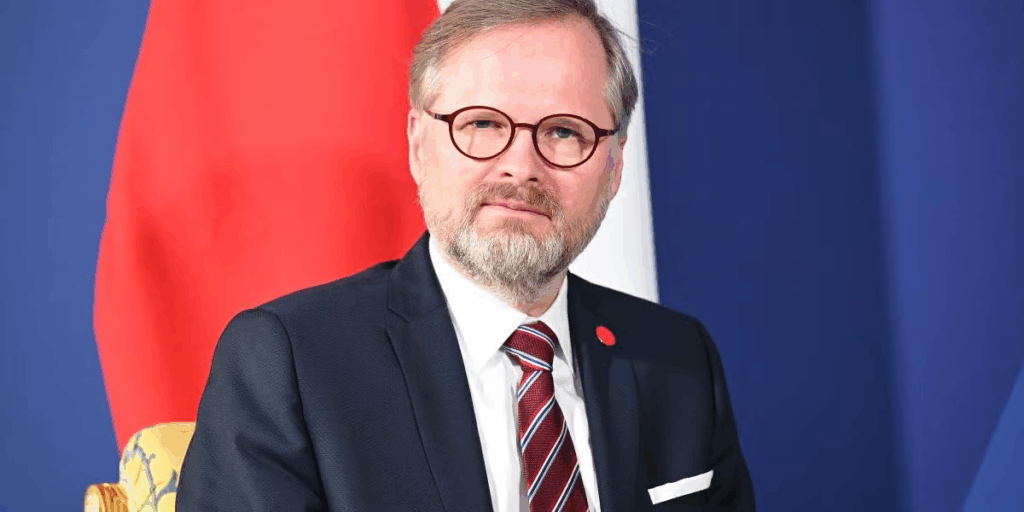

The project represents a strategic shift of production and R&D from Southeast Asia to Europe, boosting regional supply resilience while reducing emissions through localized manufacturing. Prime Minister Petr Fiala, attending the opening ceremony, said: “The opening of this state-of-the-art heat pump production facility strengthens the competitiveness of Czech industry, brings new skilled jobs, and confirms that the Czech Republic offers attractive conditions for technologically demanding and innovative projects. Our government will continue to actively support these investments.”

Aligned with Panasonic’s Green Impact strategy, the Pilsen site is operated as a Net Zero factory, powered by a rooftop 1 MW solar system and renewable energy purchases. The facility’s smart building management system reduces waste and energy use, while water conservation is achieved through rainwater capture and reuse. From 2026, its vehicle fleet will shift to electric models.

Toshikatsu Fukunaga, CEO of Panasonic HVAC Europe, highlighted the importance of the investment: “At Panasonic, we see Europe as particularly advanced when it comes to sustainability, and therefore the acceptance of sustainable energy solutions. Our investment into the Pilsen factory demonstrates both our confidence in the growth of the market and our ability to anticipate and meet future demand.”

The expansion also integrates a new R&D center in collaboration with the Technical University of Ostrava and the University of West Bohemia. By 2028, the local team will manage the full development lifecycle of air-to-water heat pumps, supported by advanced robotics, AI-driven automation, and close coordination with Panasonic’s global network.

RELATED ARTICLE: Tesla Supplier Panasonic Plans $4 Billion EV Battery Factory in Kansas

Radek Vach, Business Planning Director at Panasonic HVAC CZ, noted: “By placing further R&D capabilities and production together on the same site, we’ll be able to ensure that the factory is able to rapidly and nimbly anticipate and respond to the evolving needs of this key market. There will also be cost savings associated with reduced logistics, in addition to the speed and flexibility associated with bringing R&D and production together.”

Paul Kenny, Director General of the European Heat Pump Association, underscored the wider market impact: “The heat pump sector is boosting Europe’s energy security, our economy and our path to decarbonisation by replacing fossil fuel imports with a clean, locally made and locally powered solution. Today’s factory reopening is both a big step forward on that journey and a clear message to decision-makers from one of the world’s leading companies, that the future is bright in European manufacturing and that heat pumps will inevitably be at the heart of our future global energy system.”

With the European heat pump market valued at €12.2 billion in 2024 and forecast to exceed €71 billion by 2034, Panasonic’s investment in Pilsen positions the company as a central player in Europe’s transition to clean heating and cooling solutions.

Follow ESG News on LinkedIn